Regulator «STAR»

Regulator «STAR»

The next step in development of control and anti-surge equipment for pipeline transport.

We have created it with consideration for most demanding requirements in the industry sector.

Gazprom Organization Standard 2–4.1–212–2008:

A New Principle of Flow Regulation

The regulator operates on the basis of the optimal geometry of the flow passage. The flow does not change its direction at any point within the control zone.

Symmetrical narrowing of the passage toward the center eliminates the main problems of conventional regulators — turbulence, flow instability, and pressure loss.

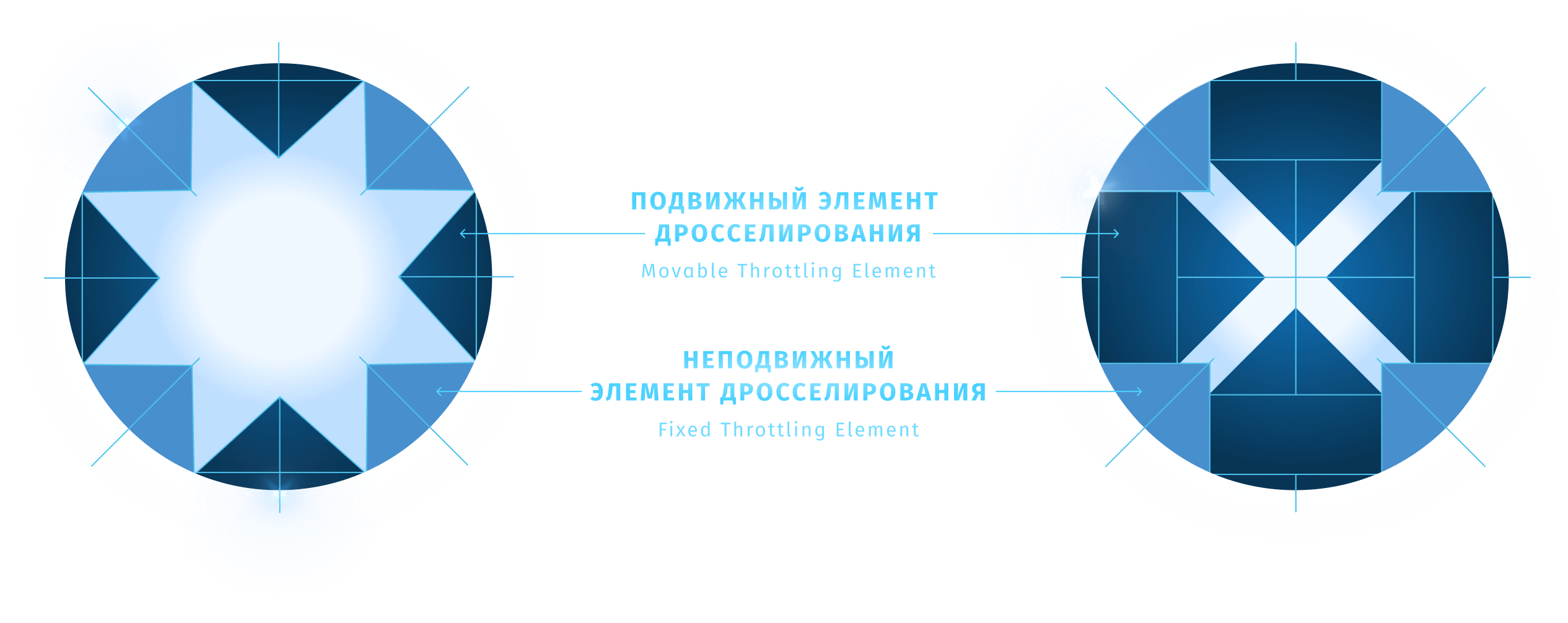

A cross-sectional diagram of the movable and fixed throttling elements (TE):

a) — fully open;

b) — change of the flow passage.

During operation, the flow narrows symmetrically toward the center without creating vortices or directional changes. The absence of obstructions in the center of the flow passage ensures smooth regulation and stable medium movement.

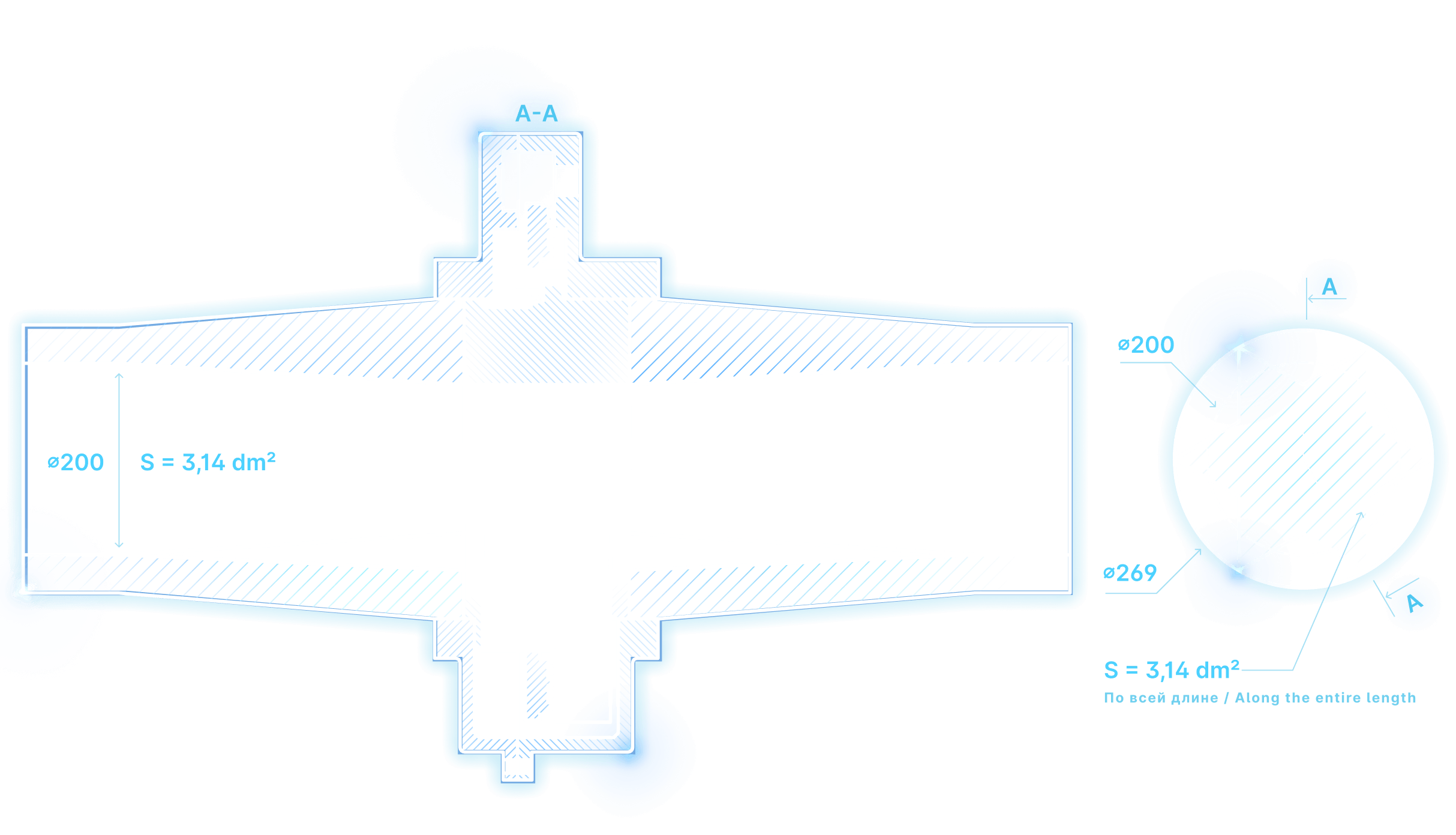

The cross-section shows that the flow passage area remains constant throughout the entire flow path (example: D = 200 mm).

Symmetrical narrowing of the passage toward the center solves all major flow-control problems found in existing equipment on the market:

• flow capacity — up to 99% of the pipeline’s potential; the “smooth pipe” principle is implemented for the first time in a regulator;

• absolute axisymmetric flow throughout the entire control range;

• no changes in flow direction whatsoever;

• preservation of the gas kinetic energy provided by compression systems or by pressure at storage and production points (reservoir pressure);

• a design-integrated capability of achieving positioning accuracy up to 0.25%.

As a result — a multiple reduction in costs associated with compensating regulation-related losses.

Advantages

Technical Specifications

A key indicator of pipeline valves is the flow capacity coefficient, which is 1.5 to 9 times higher than that of similar equipment from other manufacturers.

Reduced Energy Loss

We reduced the flow energy loss to 5% thanks to the advanced axisymmetric design of the flow passage, while energy loss indicators for regulators with a cage valve exceed 60%.

Flow Zone Heating

The world's first regulators with a built-in housing heating function. This capability is critically important when operating equipment in low-temperature conditions.

Flow Reversal

The only type of regulators that allow equivalent change of the flow direction of gas, steam, or liquid. Flow characteristics remain unchanged during reverse operation.

Self-Cleaning

The design minimizes damage to regulators caused by sand, welding slag, and other foreign particles. The maintenance interval is 2–4 times longer compared to other types of regulators.

Serviceability

We repair regulators without removing them from the system. Repair and return to operation take from several hours to a few days. Equipment from other manufacturers may require up to six months of factory-level repairs.